- Rikabgunj Hyderabad

- info@rajaramtmt.com

- 24/7 Customer Support CALL : 918790790365

About Us

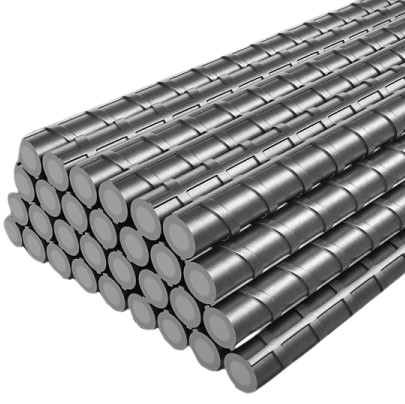

Dilip Rerolling Private Limited has redefined the industry standards with RAJARAM Thermex TMT bars. The company’s state-of the-art manufacturing plant has incorporated the latest testing techniques along with keeping a team of experts who analyze the RAW materíals and closely monitor the manufacturing process at various stages right from reheating to finishing. This ensures stringent Quality Control from the raw material stage to the finished product stage, The quality of RAJARAM Thermex TMT bars is further enhanced by German Thermex Cooling Technology. This globally acclaimed process ensures Superior strength, and ductility. perfect bonding with cement, corrosion resistance, and cost-effectiveness

Mission & Vision

Our mission at Dilip Rerolling Private Limited is to redefine industry standards by producing superior quality RAJARAM Thermex TMT bars. Through our state-of-the-art manufacturing plant and the latest testing techniques, we are committed to ensuring stringent quality control at every stage of production. Leveraging German Thermex Cooling Technology, we aim to deliver TMT bars that offer exceptional strength, ductility, perfect bonding with cement, and corrosion resistance, providing cost-effective solutions for our customers’ construction needs.

Our vision is to be a global leader in the TMT bar industry, recognized for our innovation, quality, and commitment to excellence. We aspire to set new benchmarks in manufacturing practices by continuously adopting advanced technologies and maintaining rigorous quality standards. Our goal is to contribute to the construction industry by providing high-quality, reliable, and sustainable TMT bars that enhance the durability and safety of structures worldwide.

Why Rajaram TMT

We are providing the best quality

RajaRam TMT Ltd. is certified by IS:1786 & ISO 9001-2015. RajaRam TMT

Fe 550D is made by 100% billets and chemical composition with

carbon, Sulphur and phosphorous are well in control as per IS:1786

specifications.

A strong bond is formed between RajaRam TMT bars and the surrounding concrete due to the specially designed rib pattern of RajaRam TMT Bars.

The tough outer surface and the soft core of RajaRam TMT bar make the bar bendable and ideal for construction. As per the specification of IS: 1786 for bending around much smaller mandrels, an unbreakable advantage at construction sites.

RajaRam TMT bars have low carbon content which gives it superior

weldability. No pre-warming and post welding is required in manual arc welding.

RajaRam TMT is guaranteed to be lightweight and has a lower section weight than usual.

The soft ferrite-pearlite core of RajaRam TMT bars enables them to bear dynamic & seismic loading.

RajaRam TMT conforms to IS:1786 specifications which result in excellent ductility, high bending capability, and superior welding strength.

Chemistry

IS:1786/1985

Carbon (Max %)

0.30

Manganese (%)

0.5-1.2

Sulphur &

As per IS:1786/1985

Phosphorous

RajaRam TMT

0.12-0.25

0.5-1

As per IS:1786/1985

RajaRam TMT Bar has a combination of strength and ductility that exceeds the minimum limits specified by IS: 1786. These superior values of strength and ductility represent a higher level of safety.

Features

Bendability

Weldability

Fire Resistance

Corrosion Resistance

Bondability

mazbooti ka naam rajaram

Meet the Team

Rajaram TMT Steel: Trusted by industry leaders for unparalleled quality and durability. Our clients testify to structures that stand strong for generations

CEO

CEO and Co-Founder

Manager

Fitness Instructor

CEO

CEO and Co-Founder

Manager

Fitness Instructor

About Us

The Quality Of RAJARAM Thermex TMT Bars Is Further Enhanced By German Thermex Cooling Technology. This Globally Acclaimed Process Ensures Superior Strength, And Ductility. Perfect Bonding With Cement, Corrosion Resistance, And Cost-Effectiveness.

Quick Link

Connect

info@rajaramtmt.com

OFFICE : 21-1-414, Rikabgunj, Hyderabad – 500 002, Telangana.

COMPANY : Survey No. 21 to 24 Gunded Village, balanagar Mandal, Mahboobnagar District Telangana.

CALL : 8790790365